Cement Price in Pakistan 2024 | Today Rates Update

Cement prices in Pakistan, currently ranging from Rs. 1400 to Rs. 1470 per bag, play a crucial role in shaping the construction landscape nationwide. These prices fluctuate based on market dynamics, reflecting factors such as demand, supply, and economic conditions.

Cement Price in Pakistan 2024

Brings significant insights into cement pricing in Pakistan, where prices per bag range between Rs. 1400 to Rs. 1470. For a detailed regional breakdown and specific price comparisons, please refer to the Price Table provided below.

Latest Cement Price in Pakistan

The revision in federal excise duty FED on cement bag pushed price of each 50kg bag to around Rs1330, as compared to previous price of Rs1280. The price of cement bags are expected to hit around Rs1370 in upcoming days.

Also Read:

| Company | Rate (RS) |

|---|---|

| BestWay Cement | 1325-1330 |

| Pakcem Cement | 1330-1350 |

| DG Khan Cement | 1325-1350 |

| Fauji Cement | 1295-1275 |

| Lucky Cement | 1290-1310 |

| Kohat Cement | 1290-1310 |

| Cherat Cement | 1295-1315 |

| Maple Leaf Cement | 1330-1350 |

| Askari Cement | 1295-1315 |

Factors Affecting Cement

The pricing of cement in Pakistan is influenced by several key factors that collectively shape market dynamics and consumer costs. These factors include the intricate balance between demand and supply, the prevailing economic conditions impacting construction activities, and the regulatory measures implemented by governmental authorities.

Demand and Supply Dynamics

The demand for cement in Pakistan fluctuates based on infrastructure projects, housing developments, and commercial construction activities. When demand outstrips supply, prices tend to rise as producers adjust to meet market needs.

Economic Conditions

Economic factors such as GDP growth, inflation rates, and currency stability play a crucial role in cement pricing. Economic growth typically correlates with increased construction activity and higher demand for cement, driving prices upward.

Government Policies

Government policies, including regulations on production, taxation, and infrastructure spending, significantly impact the cement industry. Policies that promote or restrict cement production and consumption can affect supply chains and pricing strategies adopted by manufacturers.

Types of Cement

A variety of cement types cater to diverse construction needs, offering specific properties and advantages. These types include Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), and White Cement.

Ordinary Portland Cement (OPC)

Ordinary Portland Cement (OPC) is the most widely used cement type in Pakistan and globally. It is known for its versatility and strength, making it suitable for a wide range of construction applications, including residential, commercial, and infrastructure projects.

Portland Pozzolana Cement (PPC)

Portland Pozzolana Cement (PPC) is a blended cement that combines Ordinary Portland Cement with pozzolanic materials such as fly ash or silica fume. This blend enhances the cement’s durability, reduces the heat of hydration, and improves workability.

White Cement

White Cement is primarily used for decorative purposes and architectural applications where aesthetics play a crucial role. It is produced from raw materials with low iron content, resulting in a white finish when mixed with pigments.

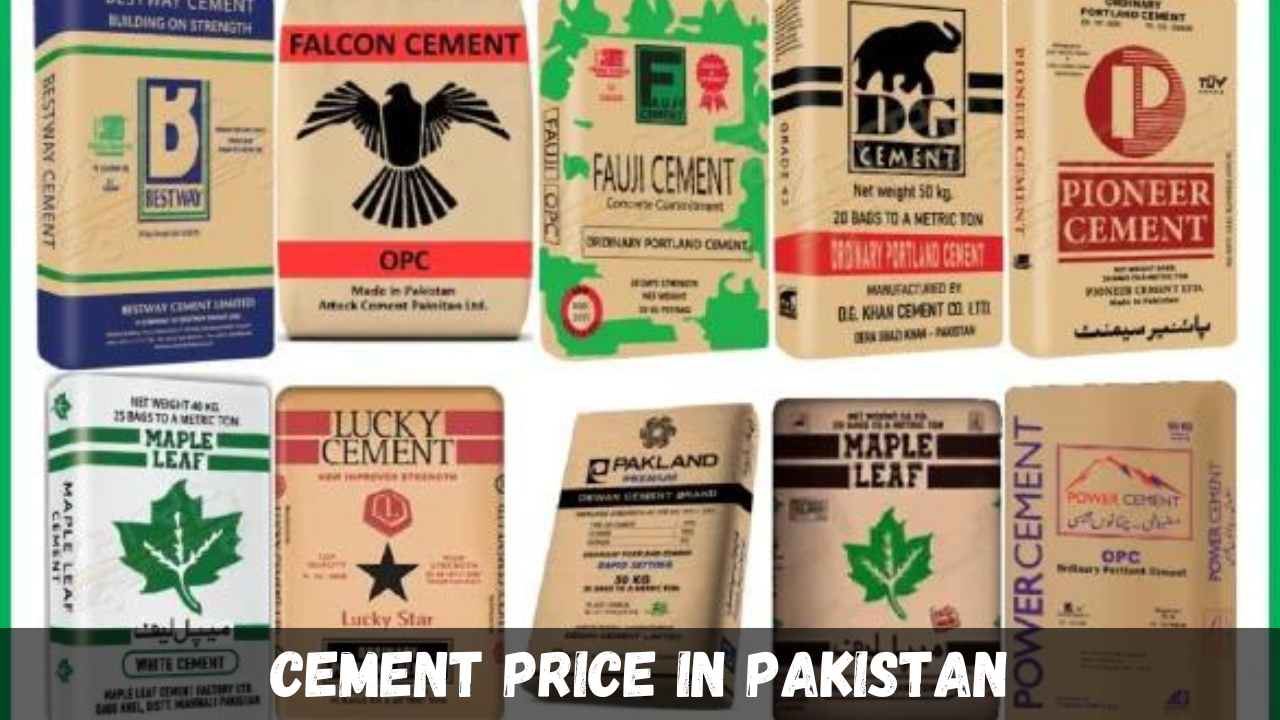

Major Cement Brands in Pakistan

- Ultra-Tech Cement. Ultratech Cement is one of the leading cement manufacturers in India. …

- ACC Cement. …

- Ambuja Cement. …

- Shree Cement. …

- Ramco Cement. …

- Birla Cement. …

- Dalmia Cement. …

- India Cements.

Sustainability and Cement Production

Sustainability is increasingly becoming a critical consideration in cement production in Pakistan. Environmental concerns surrounding cement manufacturing include carbon emissions, energy consumption, and natural resource depletion. To address these issues, the industry is exploring green cement alternatives.

Buying Tips for Consumers

- Stay Informed: Keep track of market trends and price updates regularly.

- Negotiate Contracts: Negotiate long-term contracts with suppliers for better pricing stability.

- Timing Matters: Purchase during off-peak seasons when prices tend to be lower.

- Quality Check: Prioritize quality over price to avoid compromising construction integrity.

- Explore Bulk Discounts: Buy cement in bulk to benefit from volume discounts offered by suppliers.

- Local Sourcing: Consider local suppliers to potentially reduce transportation costs.

- Plan Efficiently: Plan projects well in advance to secure cement at favorable rates and avoid rush purchases.

Impact of Cement on Construction Industry

Fluctuations in significantly impact the construction industry in Pakistan. The cost of building materials, including cement, directly influences project budgets and timelines. Higher can escalate overall construction costs, affecting the feasibility and profitability of projects.

Also Read:

Conclusion

Understanding the dynamics of cement price fluctuations is crucial for stakeholders in Pakistan’s construction sector. Cement prices play a pivotal role in shaping project economics, influencing everything from budget allocations to material procurement strategies. By staying informed about market trends, embracing sustainable practices, and strategically planning purchases, stakeholders can navigate the challenges posed by volatile cement prices effectively.

FAQs

Cement prices in Pakistan are influenced by factors such as demand-supply dynamics, economic conditions, and government policies regulating production and taxation.

Construction companies can adapt by monitoring market trends, negotiating long-term contracts with suppliers, and exploring alternative cement brands or sustainable options.

Regular monitoring helps stakeholders anticipate price fluctuations, plan budgets effectively, and optimize procurement strategies to minimize cost impacts on projects.

Green cement alternatives reduce carbon emissions, energy consumption, and natural resource depletion compared to traditional cement, aligning with sustainable development goals.

Regional factors such as infrastructure development, local demand variations, and transportation costs can cause price disparities across different regions of Pakistan, influencing consumer pricing strategies.